Swiss screw machining was introduced during the first industrial revolution as an answer to problems related to the crude machining of the time. The initial development of the Swiss screw machining process was for the manufacture of complex precision instruments that were produced by Swiss technicians. Read More…

H & R Screw Machine Products-ISO 9001-certified manufacturer of high-volume screw machine products for many industries. We also produce CNC turned parts and provide machining of customer supplied castings, forgings and stampings.

It is Thuro’s mission to be the leading choice for screw machine parts, and to offer our products at the highest quality and the lowest cost. Our team members dedicate themselves to ensuring that our customers receive the perfect part on time, every time.

Based out of California, Pacific West America, Inc. (PWA) is a metal fabrication company. We focus most of our efforts on swiss screw machining, stampings, and precision parts, and our electronics division makes products such as cable assemblies, connectors, circuit boards and membrane switches. We create our products using a variety of CNC controlled machines, processes and robotics. Such...

At M.A.R.'s Engineering, we take great pride in our ability to deliver high-quality screw machine products. Our screw machines are capable of producing complex components with utmost precision and efficiency. Whether it's small parts or intricate assemblies, we have the expertise and equipment to meet your specific requirements. With a wide range of materials and finishes available, we can...

Avanti Engineering has been a trusted partner for high-volume screw machine products and CNC turned parts since 1972. We take pride in our resources, experience, and adherence to strict ISO 9001 standards. Using cutting-edge technology, we produce high-quality, consistent components with fast turnaround times and reliable delivery. Whether you need 1,000 or 20 million parts, Avanti ensures...

At GrovTec Machining, we pride ourselves on being the go-to destination for precision turned components and screw machine products. When it comes to fulfilling your machining needs, you need not look any further than our state-of-the-art screw machine shop. Our dedicated team of experienced machinists and cutting-edge equipment allow us to tackle projects of all sizes and complexities.

At Edward Koehn Co, we are dedicated to delivering reliable and efficient solutions to our clients. With state-of-the-art equipment, experienced technicians, and a commitment to continuous improvement, we strive to exceed customer expectations and drive success in every project.

At Lakeside Screw Products, we pride ourselves on delivering exceptional screw machine products crafted with precision and quality. Our commitment to excellence is ingrained in our rigorous quality control process, ensuring that every component we produce meets the highest standards of accuracy and reliability. Since 1977, Lakeside Screw Products has been a trusted partner, providing unparalleled ...

More Swiss Screw Machining Manufacturers

The nature and types of the devices being produced required components with the most detailed and accurate structure. It was from these requirements that Swiss screw machining developed.

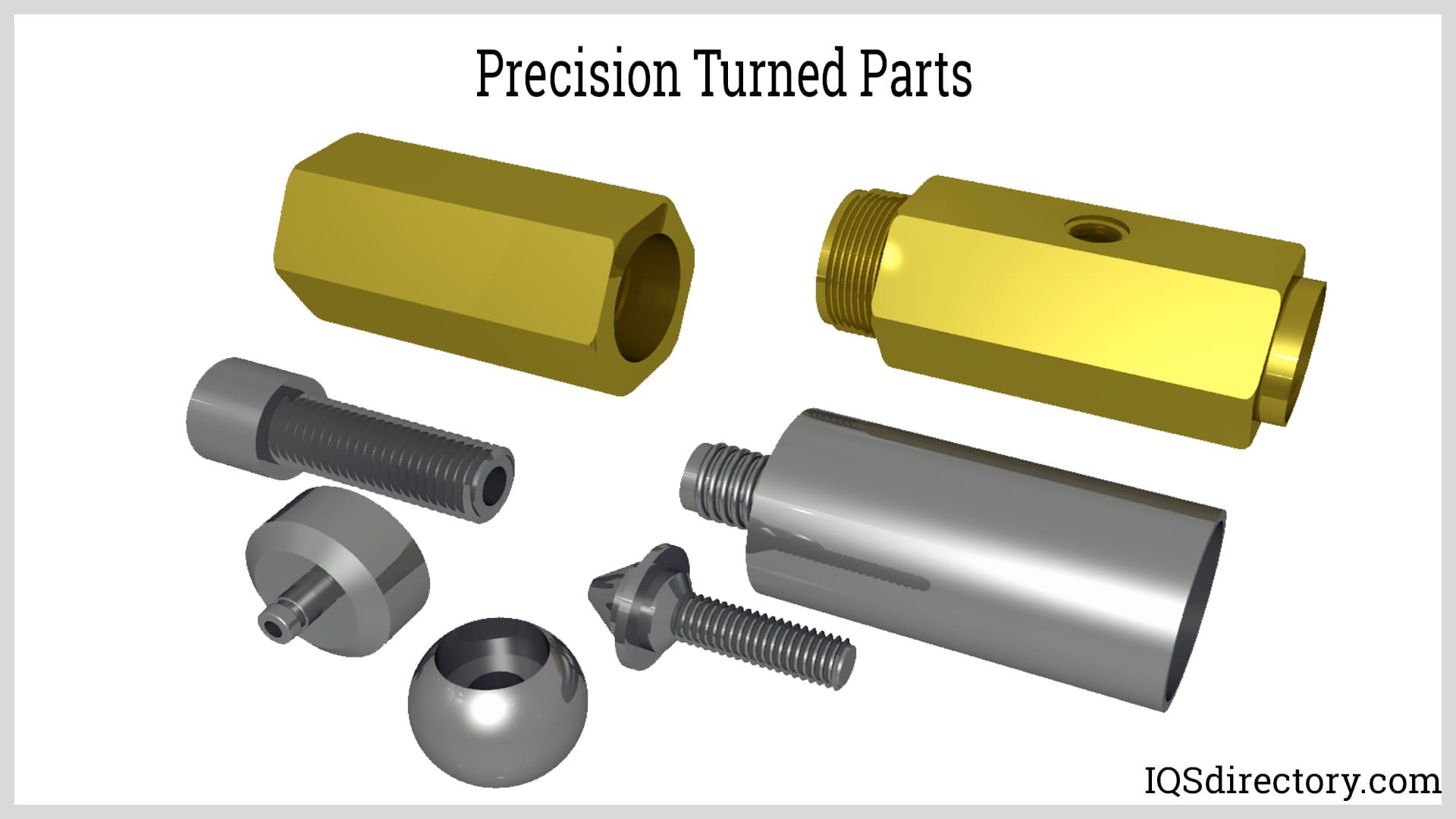

Swiss Screw Machining Components

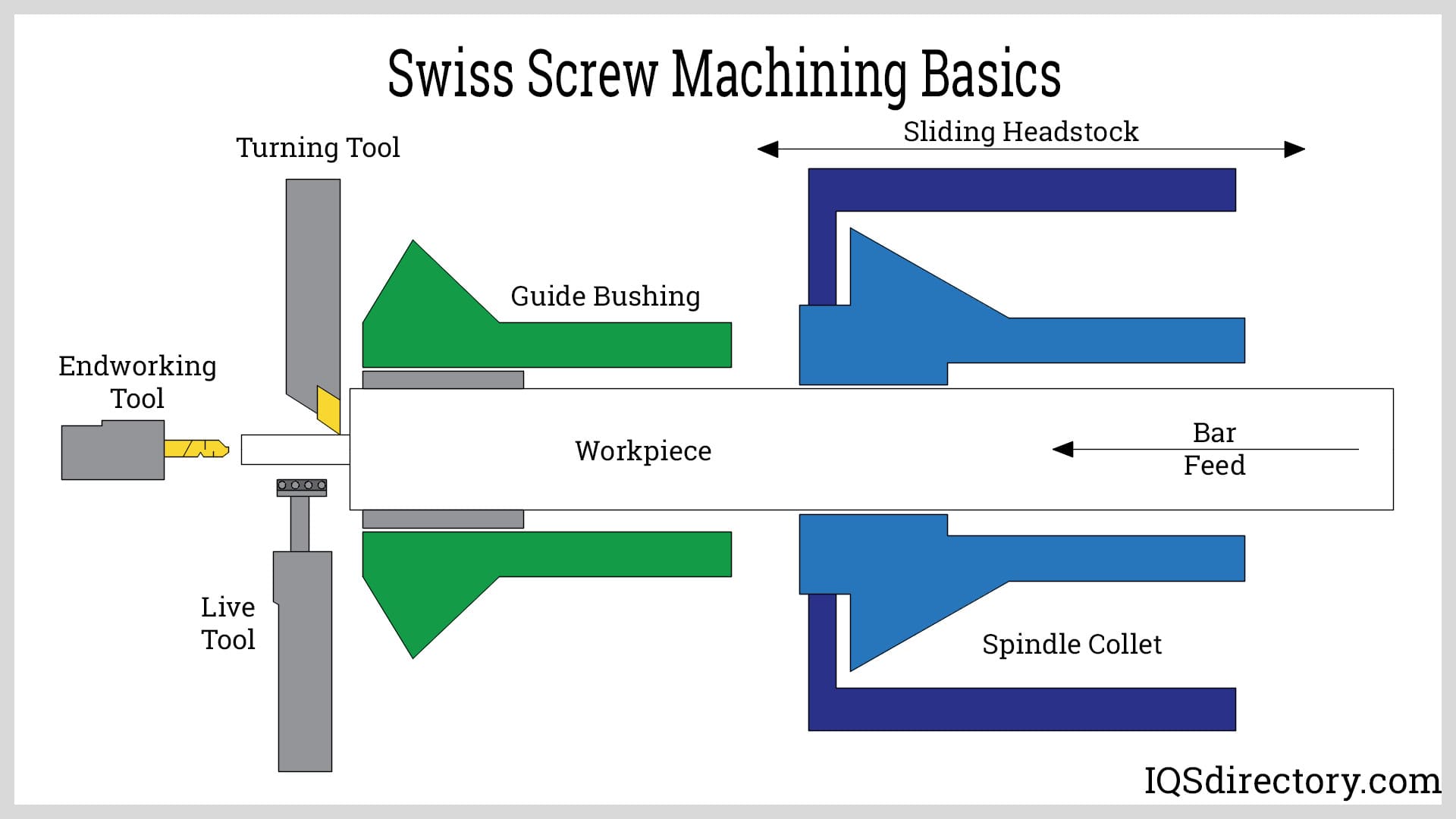

The development of Swiss screw machining has had a major impact on the machining of parts and components, especially those that have intricate and complex configurations. It is a lathe type of process that turns a workpiece to shape and forms it. In addition, Swiss screw machines can guide, slide, and move a workpiece in different directions using a headstock that has a collet that clamps and tightly holds the workpiece such that it cannot shift and rotates the workpiece when required.

Bar Feeding System

The bar stock for a Swiss screw machine is fed using a hydrodynamic or hydrostatic feed system. The difference between the two systems is in regard to how the workpiece is held while being fed. With a hydrodynamic system, a tube surrounded by pressurized oil supports and feeds the workpiece. A hydrostatic system guides the workpiece using channels or bushings. These automatic feeding systems were developed to replace the manual feed method of the original Swiss screw machines.

Collet

The collet is an essential part of the Swiss screw machine mechanism and is one of the factors that differentiates Swiss screw machines from a traditional lathe. The collet or chucking collet consists of a jaw power chuck, hydraulic cylinder, and a drawtube. A hydraulic piston opens and closes the jaws of the collet while the drawtube moves a plunger in the collet body to move the collet back and forth converting axial motion into radial motion.

Guide Bushing

Guide bushings are another factor of Swiss screw machines that differentiates them from a traditional lathe. They are the part of the mechanism that supports the workpiece during machining and prevents deflection. Guide bushings make it possible for tools to make deep cuts in one pass instead of having to make multiple passes to achieve the same results. They have a micron tolerance of 0.0002 in (0.00508 mm). The types of guide bushings used in Swiss screw machines are rotary, fixed, and high-precision.

Headstock

The headstock is the part of a Swiss screw machine that makes it possible to move a workpiece along the Z axis. The collet clamps the workpiece and is connected to the headstock, which moves the collet and the workpiece. It rotates and positions the workpiece for the machining process. The movement of the headstock exposes the workpiece to the cutting tools from the spindle and positions the workpiece at the appropriate angle.

Spindle

All of the other parts of a Swiss screw machine are useless without the spindle, which carries the machining tools. Depending on whether a Swiss screw machine is automatic or computer numerically controlled (CNC), the number of tools can include a wide variety of tooling methods. The spindle moves the tools along the X, Y, and Z axes such that the tools can make the required cuts, which includes turning, drilling, milling, threading, and cross drilling, to name a few. The spindle is mounted on the bed of a Swiss screw machine between the headstock and feed system.

Common Types of Swiss Screw Machines

Although there are several manufacturers that produce proprietary versions of Swiss screw machines, essentially, the two types that are used the most are automatic and CNC, which have different technologies.

Automatic Swiss Screw Machines

Automatic Swiss screw machines are disc cam operated with the disc cam used to change rotary motion to up and down or side to side motion by changing the positioning of the headstock for the positioning of the workpiece. An automatic Swiss screw machine is capable of performing all of the machining and cutting functions of the more advanced CNC Swiss screw machine but without computerization and the other technological advancements.

CNC Swiss Screw Machines

The major difference between the two Swiss screw machines is the computerized elements that are a part of a CNC Swiss screw machine. In essence, CNC Swiss screw machines are a very large computerized machining method that receives computer commands in the form of codes that are labeled G or M. The codes tell the parts of a Swiss screw machine when to cut, thread, or drill and when to stop. The form of the codes is similar to computer programming and comes in a long list of instructions that stipulates the most minute actions of the machine.

A major advancement that is common in CNC Swiss screw machines is the ability to have a wider range of tools. This aspect of CNC Swiss screw machines is due the inclusion of two spindles, which increases tool potential and cutting actions. Additionally, the programming aspect of CNC Swiss screw machines makes it possible for multiple machining functions to be completed at the same time, which speeds up production and enables the completion of more parts.

In modern manufacturing, the technologically advanced and computerized CNC Swiss screw machines are more widely used regardless of their cost. Small machine shops still use automated Swiss screw machines since they do not require the production volume of larger manufacturing operations.

Conclusion

The development of Swiss screw machining has made a major impact on the precision and accuracy of manufacturing. The close adherence to details and the ability to produce components with exceptional tolerances has led to a rapid use in the demand for Swiss screw machines. Although lathes are capable of turning and machining all forms of machine parts, they lack the accuracy and tight tolerances that are found in Swiss screw machines.

In the 21st century, the demand for quality and close tolerances has been rapidly increasing. Swiss screw machining is a major factor in the enhancements and improvements associated with modern manufacturing.

Broaching

Broaching CNC Machining

CNC Machining Expanded Metals

Expanded Metals Laser Cutting

Laser Cutting Metal Etching

Metal Etching Metal Fabrication

Metal Fabrication Perforated Metals

Perforated Metals Screw Machine Products

Screw Machine Products Metal Stampings

Metal Stampings Sheet Metal Fabrication

Sheet Metal Fabrication Tube Fabrication

Tube Fabrication Water Jet Cutting

Water Jet Cutting Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services