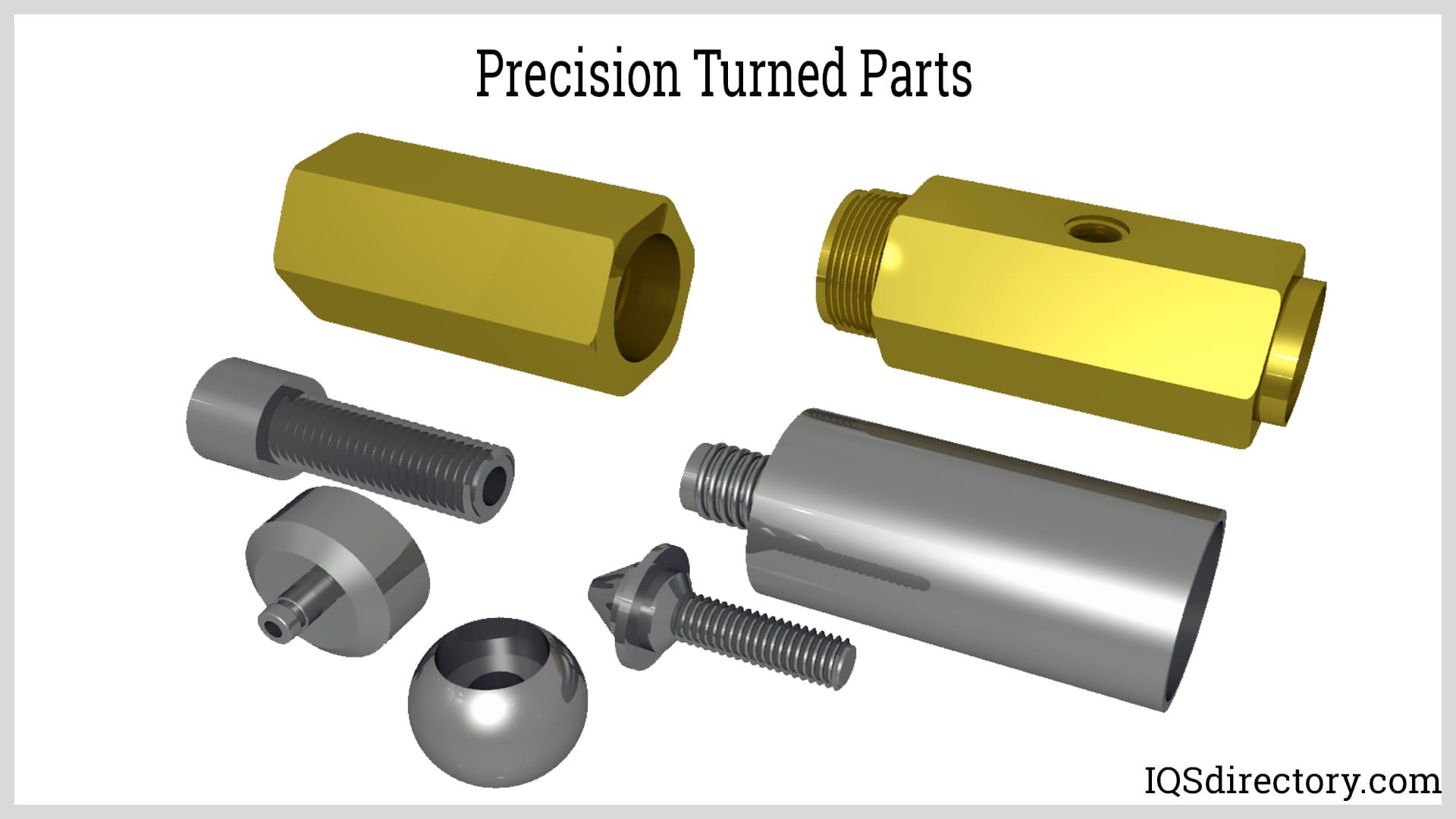

Complex pieces that are often cylindrical and threaded are called screw machine parts. These parts are employed in the production of an infinite number of products as well as for building and maintenance purposes.Read More…

H & R Screw Machine Products-ISO 9001-certified manufacturer of high-volume screw machine products for many industries. We also produce CNC turned parts and provide machining of customer supplied castings, forgings and stampings.

It is Thuro’s mission to be the leading choice for screw machine parts, and to offer our products at the highest quality and the lowest cost. Our team members dedicate themselves to ensuring that our customers receive the perfect part on time, every time.

Based out of California, Pacific West America, Inc. (PWA) is a metal fabrication company. We focus most of our efforts on swiss screw machining, stampings, and precision parts, and our electronics division makes products such as cable assemblies, connectors, circuit boards and membrane switches. We create our products using a variety of CNC controlled machines, processes and robotics. Such...

At M.A.R.'s Engineering, we take great pride in our ability to deliver high-quality screw machine products. Our screw machines are capable of producing complex components with utmost precision and efficiency. Whether it's small parts or intricate assemblies, we have the expertise and equipment to meet your specific requirements. With a wide range of materials and finishes available, we can...

Avanti Engineering has been a trusted partner for high-volume screw machine products and CNC turned parts since 1972. We take pride in our resources, experience, and adherence to strict ISO 9001 standards. Using cutting-edge technology, we produce high-quality, consistent components with fast turnaround times and reliable delivery. Whether you need 1,000 or 20 million parts, Avanti ensures...

At GrovTec Machining, we pride ourselves on being the go-to destination for precision turned components and screw machine products. When it comes to fulfilling your machining needs, you need not look any further than our state-of-the-art screw machine shop. Our dedicated team of experienced machinists and cutting-edge equipment allow us to tackle projects of all sizes and complexities.

At Edward Koehn Co, we are dedicated to delivering reliable and efficient solutions to our clients. With state-of-the-art equipment, experienced technicians, and a commitment to continuous improvement, we strive to exceed customer expectations and drive success in every project.

At Lakeside Screw Products, we pride ourselves on delivering exceptional screw machine products crafted with precision and quality. Our commitment to excellence is ingrained in our rigorous quality control process, ensuring that every component we produce meets the highest standards of accuracy and reliability. Since 1977, Lakeside Screw Products has been a trusted partner, providing unparalleled ...

More Screw Machine Part Manufacturers

They can create items at high speeds and may have numerous spindles, with a six-spindle machine being the most typical arrangement. A family of automatic lathes for tiny to medium-sized parts is known as a screw machine product. Since they no longer produce screws or screw anything into place, the moniker, "screw machine," is thought to be a little deceptive.

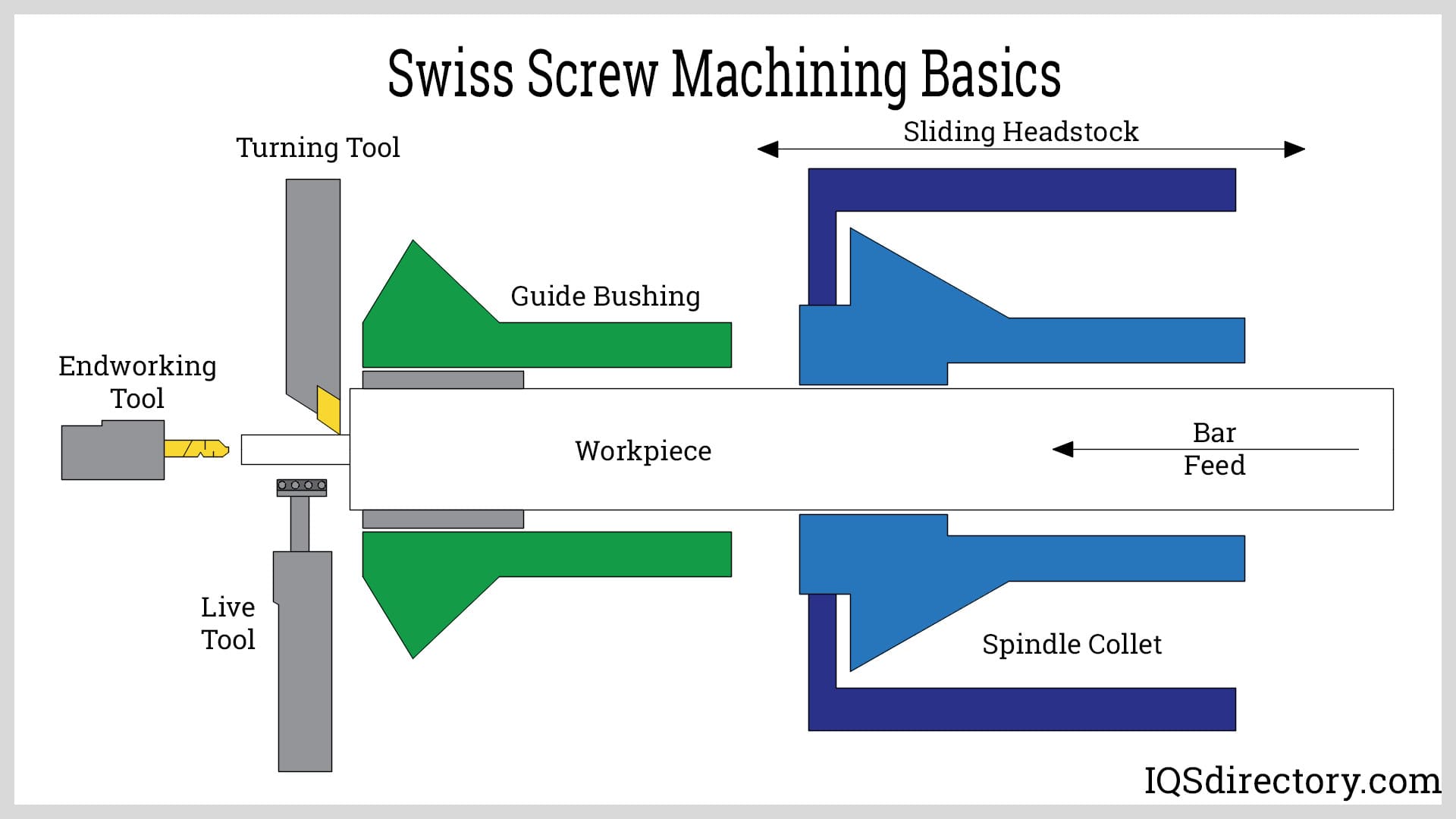

They rotate on a revolving lathe instead, effectively shaving the metal to the appropriate size. A revolving component called a disc cam, which is used in screw machines, converts rotary motion into linear motion or vice versa utilizing one or more spindles. A screw machine runs with close spindle collets, which reduces or completely eliminates deflected debris.

Types of Screw Machines

A disc cam is used in automatic Swiss screw machines to rotate tools in the direction of the workpiece area, which is fixed in place by a number of spindle collets arranged side by side. Computer precision parts can be produced with numerically-controlled machines by using a CNC unit to operate the tools. Swiss screw CNC machines, commonly referred to as CNC lathes, provide numerous axes of motion for quick results.

Although they can be labor-intensive to set up properly, screw machines—both automatic and CNC-driven—are economical when producing numerous pieces. They frequently aren't the best option for sporadic prototyping. However, they are a flexible option when making parts out of many sorts of metals because of the large range of metals they work with.

Differences Between Mechanical and CNC Screw Machining

Given that each machine type has benefits and drawbacks, choosing between a mechanical screw machine and a CNC screw machine could prove challenging. Traditional screw machines, for instance, cost more upfront for smaller runs but can efficiently manufacture big volumes of output. Additionally, they work much more quickly than their CNC-operated competitors. Although slower, CNC machines are more cost-effective for small batches and can maintain tighter tolerances.

Screw machining achieves precision and tolerances that are difficult to match. Other metal fabrication and forming techniques rarely produce items with a screw machine's level of excellence. Screw machines are perhaps the best tools available for creating turned pieces.

Benefits of CNC Screw Machine

- An automatic Swiss screw machine may not be able to provide the same level of control as CNC machining. The usage of several axes with the CNC unit enables the use of more tool sets for milling and turning. With the use of CNC capabilities, cycle times may be shortened and more intricate parts can be produced. Using a CNC Swiss machine, several tasks can be completed more quickly. A CNC Swiss screw machine has an accuracy range of 0.0002 to 0.0005 inches and can rotate an item up to 10,000 RPM. A CNC Swiss lathe is not only more accurate, but it also produces less waste and offers greater flexibility when cutting a particular product.

- Two goods could be produced at once on a single-spindle machine. When compared to a single-spindle, a multi-spindle machine typically has six main spindles, enabling users to produce six times as much. As a result, manufacturing times are shortened, and space and energy consumption in the factory are reduced.

- Electricity savings can assist in offsetting the expenses of upkeep, improving safety and equipment, and having greater space can open up prospects for more equipment and worker safety. Overall, the advantages of multi-spindle screw machines result in time and money savings.

Choosing the Proper Screw Machine Parts Supplier

To make sure you have the most positive outcome when purchasing screw machine parts from a screw machine parts supplier, it is important to compare at least 4 to 5 companies using our list of screw machine parts suppliers. Each screw machine parts company has a business profile page that highlights their areas of experience and capabilities and a contact form to directly communicate with the supplier for more information or request a quote. Review each screw machine parts company website using our patented website previewer to get an idea of what each business specializes in, and then use our simple RFQ form to contact multiple screw machine part companies with the same form.

Broaching

Broaching CNC Machining

CNC Machining Expanded Metals

Expanded Metals Laser Cutting

Laser Cutting Metal Etching

Metal Etching Metal Fabrication

Metal Fabrication Perforated Metals

Perforated Metals Screw Machine Products

Screw Machine Products Metal Stampings

Metal Stampings Sheet Metal Fabrication

Sheet Metal Fabrication Tube Fabrication

Tube Fabrication Water Jet Cutting

Water Jet Cutting Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services