Products produced for the modern industry must meet the highest possible standards and tolerances, necessitate the highest quality, and meet demanding specifications. Various turning processes are used to manufacture precision-turned products that meet and exceed the challenges of manufacturers. Read More…

H & R Screw Machine Products-ISO 9001-certified manufacturer of high-volume screw machine products for many industries. We also produce CNC turned parts and provide machining of customer supplied castings, forgings and stampings.

It is Thuro’s mission to be the leading choice for screw machine parts, and to offer our products at the highest quality and the lowest cost. Our team members dedicate themselves to ensuring that our customers receive the perfect part on time, every time.

Based out of California, Pacific West America, Inc. (PWA) is a metal fabrication company. We focus most of our efforts on swiss screw machining, stampings, and precision parts, and our electronics division makes products such as cable assemblies, connectors, circuit boards and membrane switches. We create our products using a variety of CNC controlled machines, processes and robotics. Such...

At M.A.R.'s Engineering, we take great pride in our ability to deliver high-quality screw machine products. Our screw machines are capable of producing complex components with utmost precision and efficiency. Whether it's small parts or intricate assemblies, we have the expertise and equipment to meet your specific requirements. With a wide range of materials and finishes available, we can...

Avanti Engineering has been a trusted partner for high-volume screw machine products and CNC turned parts since 1972. We take pride in our resources, experience, and adherence to strict ISO 9001 standards. Using cutting-edge technology, we produce high-quality, consistent components with fast turnaround times and reliable delivery. Whether you need 1,000 or 20 million parts, Avanti ensures...

At GrovTec Machining, we pride ourselves on being the go-to destination for precision turned components and screw machine products. When it comes to fulfilling your machining needs, you need not look any further than our state-of-the-art screw machine shop. Our dedicated team of experienced machinists and cutting-edge equipment allow us to tackle projects of all sizes and complexities.

At Edward Koehn Co, we are dedicated to delivering reliable and efficient solutions to our clients. With state-of-the-art equipment, experienced technicians, and a commitment to continuous improvement, we strive to exceed customer expectations and drive success in every project.

At Lakeside Screw Products, we pride ourselves on delivering exceptional screw machine products crafted with precision and quality. Our commitment to excellence is ingrained in our rigorous quality control process, ensuring that every component we produce meets the highest standards of accuracy and reliability. Since 1977, Lakeside Screw Products has been a trusted partner, providing unparalleled ...

More Precision Turned Product Manufacturers

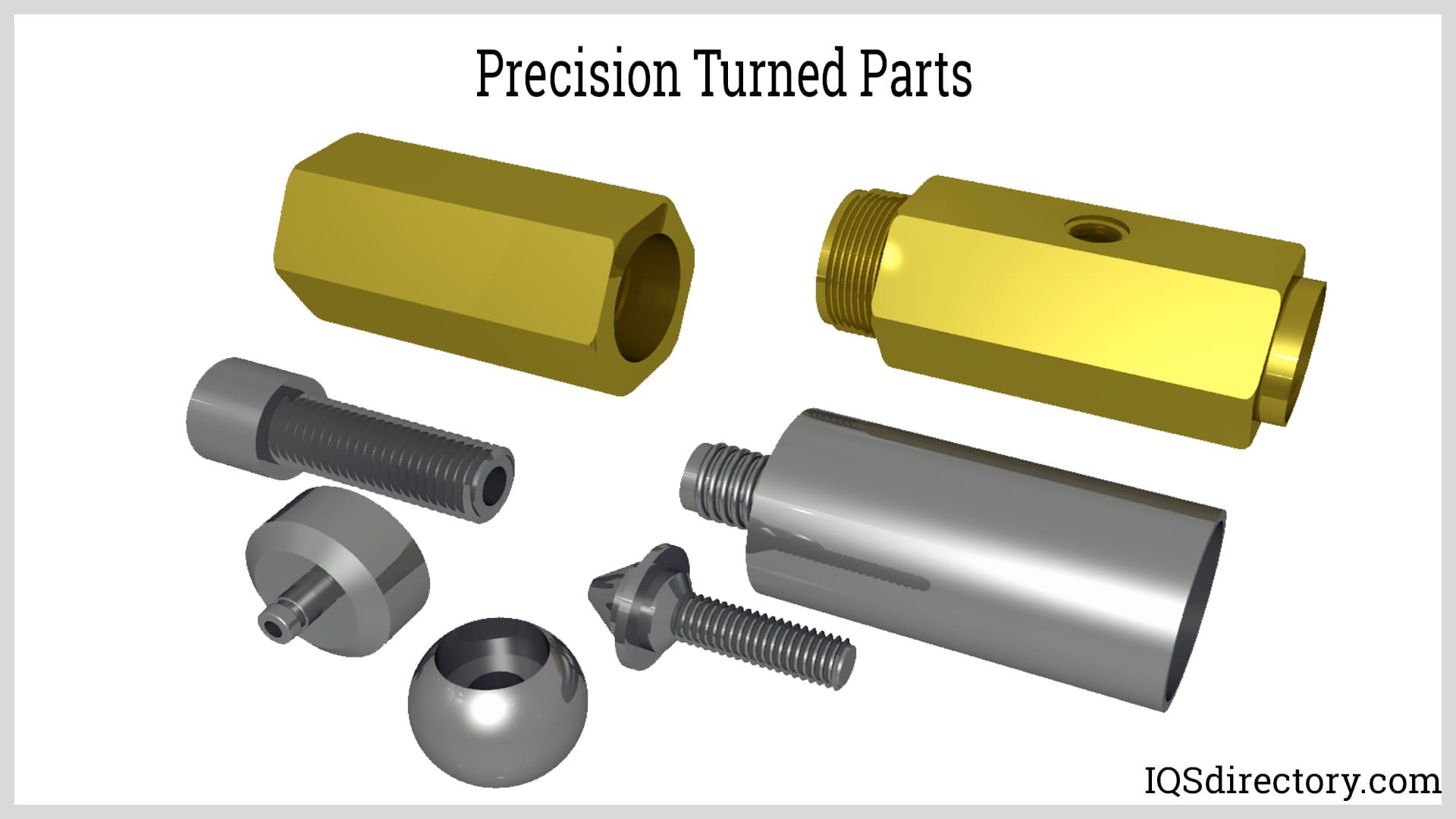

These components have the precision, accuracy, and tolerances required by 21st-century products.

There is an endless number of precision-turned products used for industrial products and applications. Precision turning produces products for complex machinery in high volume to meet the ever-increasing demand for intricate components. Parts are turned and cut to reach the necessary tolerances.

Fittings

Fittings are used as connectors that join two or more pieces securely such that the joined parts are unable to shift. They are made from a variety of materials including copper, cast iron, steel, brass, and aluminum. For lighter connections, special types of plastics are used. The various forms of fittings are capable of joining components that have different configurations, dimensions, and shapes.

Under normal conditions, the pieces to be joined are of the same material. However, that is not always the case and it’s necessary to take extra care in connecting a fitting. Fittings are threaded connectors that are turned with precision to exactly meet the requirements of a connection. Precision turning is necessary for producing accurate fittings, which can include threads on their interior or exterior.

Bushings

Bushings are a special form of precision-turned product that is used to reduce the surface friction between components and ensure their alignment. They are used to support rotating and sliding shafts and are precision made such that their dimensions are uniform and precise. Bushings are thin tubes that improve the efficiency of shafts and assist in reducing vibrations that produce noise.

There is a wide variety of bushings that are available in shapes, sizes, and dimensions with custom produced bushings for special applications. As new devices and processes are introduced, new forms of bushings are required to provide the support, security, and strength for any form of metal or material. The nature of bushings, which is to reduce friction and serve as a replacement for lubrication, is one of the main reasons for the growing demand for their use.

The types of bushings include suspension bushings, flanged bushings, sleeve bushings, and drill jig bushings. The many applications for bushings require that they be precision manufactured to meet the most demanding standards and requirements.

Flanges

A common form of precision turned product is flanges, which are circular shapes used to connect pipes and are an essential part of spacing parts along the edge of a structure. There are many forms of flanges with each form designed for a special or unique application. The wide assortment of sizes and shapes is necessary to meet the many applications for which they are required. They are made of highly durable materials in order to endure the stress and pressure they have to endure.

The turning of flanges, as with most precision turned products, has to be highly precise such that they exactly meet the requirements of an application. Slight flaws or inaccuracies can damage equipment, cause failures, and allow for leaks in piping.

Spacers

Spacers are one of the simplest forms of turned precision products, which are a vital part of machines and processes. The purpose of spacers is to fill gaps and openings that are small but can influence the performance of a machine. Since exact dimensions are a necessity for spacers, they are very carefully turned such that they meet the dimensional requirements. Aside from balancing and correcting spacing errors, spacers prevent noises from vibrations that can damage equipment and products.

Pulleys

Of the various types of precision products, pulleys require the greatest accuracy due to their function, which is to change the direction of applied force and reduce the amount of force necessary to move heavy objects. The nature of the work of pulleys requires exceptional accuracy from precision turning. The dimensions and configurations of pulleys have to meet the highest tolerances and requirements. Since pulleys are used in combination, their dimensions have to be such that the union of pulleys perfectly matches for safety reasons and the reduction of the energy required to move a weight.

Unlike other turned parts, pulleys require a set of machining operations to meet dimensional requirements and the type of pulley. The main characteristic of pulleys that is carefully machined is the depth of their groove, which has to be adjusted for the type of chain, wire, rope, or cable the pulley will move. In special cases, teeth are added to the grooves of a pulley to grip a chain, rope, or cable.

Benefits of Precision Turned Products

Precision turned products are an essential part of a wide assortment of processes, machines, equipment, and operations. Their accuracy, strength, durability, and resilience has made them one of the most dependable parts of several applications. Their tight tolerances have made it possible for manufacturers to produce products that are reliable and dependable.

Accuracy

The success of precision turning is due to their accuracy in transforming pieces of metal into useful products with exceptional tolerances. It is for this single characteristic that precision turned products are so popular, necessary, and widely used.

Consistency

Every precision turned product is manufactured with the same dimensions, shape, size and quality due to the precision control the turning process provides. Computer aided designs (CAD) are perfectly reproduced to the most minute detail using precision turning. The consistency of the process ensures that parts are reliable and flawless down to the smallest detail.

Cost

The high volume of precision turned parts radically reduces the cost of individual parts regardless of the complexity and intricacy of a part. Each individual part is produced quickly and efficiently to meet any form of delivery requirements. The speed of production, high volume, and rapid delivery increases profits and provides a competitive advantage.

Strength

Part of the durability of precision turned products is due to the many types of materials that are used to produce them, which varies from the hardest steels to the most resilient plastics. In addition to the strength of materials, precision turned products have to meet the highest of standards to comply with the turning process. The strength of precision turned products enables them to endure the harshest and most demanding of environments and conditions.

Waste

Another factor that reduces the cost of precision turned products is the minimal amount of waste that is produced by the process. The accuracy, control, and precision of the turning process radically reduces the amount of waste that is produced. Unlike die casting and forging, the turning process removes the least amount of material due to the precision of the process.

The five benefits listed above are a small sampling of the many benefits that precision turning achieves to produce the strongest and most durable of products, components, and parts. The precision turning process aligns perfectly with the goals and requirements of modern industry where product quality depends on the highest quality of materials and production methods.

Broaching

Broaching CNC Machining

CNC Machining Expanded Metals

Expanded Metals Laser Cutting

Laser Cutting Metal Etching

Metal Etching Metal Fabrication

Metal Fabrication Perforated Metals

Perforated Metals Screw Machine Products

Screw Machine Products Metal Stampings

Metal Stampings Sheet Metal Fabrication

Sheet Metal Fabrication Tube Fabrication

Tube Fabrication Water Jet Cutting

Water Jet Cutting Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services